The 1994 4.0L V6 Ford Explorer/Ranger is equipped with the E.E.C IV system and so its computer has 60 pins.

Ford TFI gray remote-mount module wiring diagram. Dave is a certified Ford EEC, Advanced Engine. TFI module with the EEC-IV computer system in 1983, and for. Rewiring a Ford EEC IV 'speed density' harness to a 'mass air' harness. Hi, Ken Collins here, I've added a companion video to my 5.0L engine swap two volume series on wiring a 'speed density' EEC harness over to a 'mass air' harn. The EEC-V PCM has a 104 pin connector and on the back side of the connector (wire side) are embossed a few numbers (on the back side) to further aid you in correctly identifying the pins (circuits). IMPORTANT: The illustration above and pin-out table below apply only to: 1996 Ford pickup with 4.9L, 5.0L, 5.8L engine with 4R70W or E4OD automatic.

Whether you're tracing down an electrical short or testing one of the input/output components of the PCM, pinout charts come in handy. Below you'll find the description of each pin.

| 1994 4.0L Ford Explorer/Ranger 60 Pin Connector | ||

|---|---|---|

| Pin | Wire Color | Description |

| 1 | YEL | Keep Alive Power (KAPWR) |

| 2 | LT GRN | Brake On-Off (BOO) Switch |

| 3 | GRY/BLK | Vehicle Speed Sensor (VSS) (+) |

| 4 | TAN/YEL | Ignition Diagnostic Monitor (IDM) |

| 5 | -- | Not Used |

| 6 | PNK/ORG | Vehicle Speed Sensor (VSS) (-) |

| 7 | LT GRN/RED | Engine Coolant Temp (ECT) Sensor |

| 8 | DK GRN/YEL | Fuel Pump Monitor (FPM) |

| 9 | PNK/LT BLU | MAF Ground |

| 10 | DK GRN/ORG | A/C Compressor |

| 11 | -- | Not Used |

| 12 | -- | Not Used |

| 13 | -- | Not Used |

| 14 | LT BLU/RED | MAF Signal |

| 15 | TAN/LT BLU | MAF Ground |

| 16 | ORG/RED | Ignition Module Ground |

| 17 | PNK/LT GRN | Check Engine Light (CEL) |

| 18 | -- | Not Used |

| 19 | -- | Not Used |

| 20 | BLK/LT GRN | Case Ground |

| 21 | WHT/LT BLU | Idle Air Control (IAC) Valve |

| 22 | LT BLU/ORG | Fuel Pump Relay Control |

| 23 | -- | Not Used |

| 24 | -- | Not Used |

| 25 | GRY | Intake Air Temp (IAT) Sensor |

| 26 | BRN/WHT | VREF (5 Volt Reference - EGR Position Sensor, TPS, MAP Sensor) |

| 27 | -- | Not Used |

| 28 | TAN/ORG | Data (+) |

| 29 | GRY/LT BLU | O2 Sensor 1 |

| 30 | LT BLU/YEL | Clutch Switch (MT only) Park Neutral Safety Switch (AT only). |

| 31 | GRY/YEL | Canister Purge (CANP) Solenoid |

| 32 | -- | Not Used |

| 33 | -- | Not Used |

| 34 | --- | Not Used |

| 35 | -- | Not Used |

| 36 | PNK | SPOUT |

| 37 | RED | Ignition Battery Power |

| 38 | -- | Not Used |

| 39 | RED/BLK | O2 Sensor 2 |

| 40 | BLK/WHT | PWR Ground |

| 41 | -- | Not Used |

| 42 | -- | Not Used |

| 43 | -- | Not Used |

| 44 | DK GRN | Octane Adjust |

| 45 | -- | Not Used |

| 46 | GRY/RED | Signal Return (Sensor Ground) |

| 47 | GRY/WHT | Throttle Position Sensor (TPS) Signal |

| 48 | WHT/PPL | Self Test Input (STI) |

| 49 | GRY/RED | Ground |

| 50 | -- | Not Used |

| 51 | -- | Not Used |

| 52 | ORG/YEL | Shift Solenoid 3-4 |

| 53 | PPL/YEL | Torque Convertor Clutch Solenoid |

| 54 | PNK/YEL | Air Conditioning |

| 55 | -- | Not Used |

| 56 | GRY/ORG | Profile Ignition Pickup (PIP) |

| 57 | RED | VPWR (From PCM Power Relay) |

| 58 | TAN | Injector Bank 1 |

| 59 | WHT | Injector Bank 2 |

| 60 | BLK/WHT | Power Ground |

Safety Precautions

Here are some very important safety precautions when testing the wires coming out of the 60 pin PCM connector.

- If one or any of the wires on your Ford pickup DO NOT match the color stated in the pin out charts, then you should not use the pin out charts in this article. Why? Because this is the clearest indication that these ARE NOT the connector pin out charts for your particular Ford 4.0L Explorer or 4.0L Ford Ranger.

- Never probe the front of the connector.

- You should use a wire piercing probe and probe the wire a few inches away from the connector.

- To see what this tool looks like: Wire Piercing Probe.

- You should use a back-probe.

- You should use a wire piercing probe and probe the wire a few inches away from the connector.

- You should never disconnect any of the PCM connectors without first disconnecting the battery negative terminal.

Disclaimer

I've made every effort to double and triple check the above info (and in the next couple of pages) and I've used the best sources to compile it, but nothing in life is perfect. I don't have a staff of proof readers or editors, I'm just a little guy typing this stuff up in my spare time to help and give back to the Do-It-Yourself community. So without further ado, here's my disclaimer:

© copyright Abraham Torres-Arredondo: This information is distributed in the hope that it will be useful, but WITHOUT ANY WARRANTY; without even the implied warranty of MERCHANTABILITY or FITNESS FOR A PARTICULAR PURPOSE.

If you do spot errors, please let me know. You can use the contact form at the end of the article.

If this info really saved the day, buy me a beer!

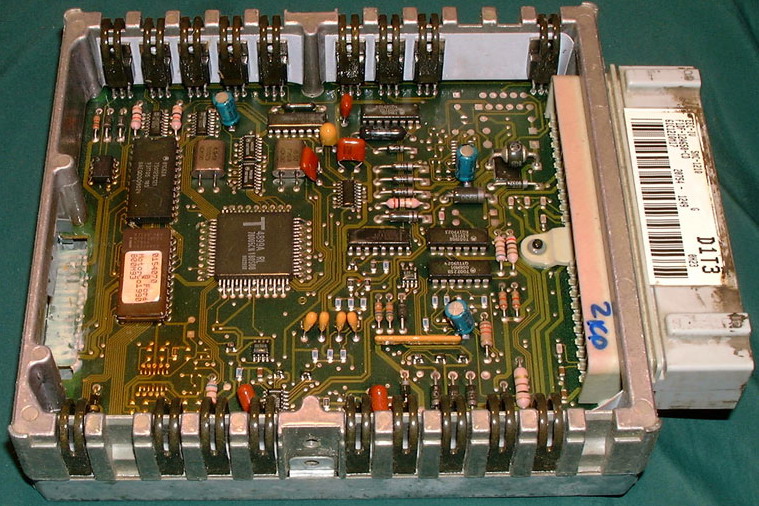

EEC Computers

EEC stands for Electronic Engine Control; and it is the computer which Ford uses to electronicly control vehicle functions. Don't think about your home computer; this one does not crash and needs almost no attention. Fuel injection computers are part of a broader title called Programmable Fuel Management Systems, whose main function is to supply a mixture of fuel and air to the engine that can be easily ignited by spark to produce reliable efficient power. Sounds simple enough. The name 'Electronic Engine Control' is commonly abbreviated to EEC but pronounced as 'eek.' This computer has chips for memory, micro-relays to control actuators, a processor to run the show, and a program to keep it all working smoothly. It looks to sensors to learn what environment the engine is operating in. It also looks at driver inputs to learn what you want to do. It processes the information it receives and calculates what the best fuel mixture and timing setting should be. It then activates those actuators to implement the previously calculated fuel mixture and timing. It cycles back to listen to the sensors again to insure the outcome was what the driver and computer wanted. All that happens in a millisecond and repeats at speeds so fast it can adjust calculations between firing cylinders at 6000+RPM. When it's all working in harmony it will last for over 30 years with only basic maintenance.

Ford started putting EEC in vehicles starting in 1978. There have been 8 versions of EEC, but not all of them are interesting to most EFI novices or useful. I'll cover the different versions quickly.

EEC-I

*1978

*Ignition timing, EGR, and Smog pump

EEC-II

*1979

*Carb (O2 feedback and fuel stepper motor), Ignition timing, EGR, and Smog pump

EEC-III

*1980

*Central Fuel Injection (no Self-Test functions)

EEC-IV

*1984

*OBD-I (covered in text below)

EEC-V

*1994

*OBD-II (covered in text below)

EEC-VI

*2003

*Multiple connectors

*No J3 connector for chips, complete Flash Memory capable

Unfortunately American capitalism drives Ford, 'just because you making a new toy doesn't mean you can't sell the old toys until they're gone.' This is called crossover, there were carburetors in 1988, and many other crossovers that make pinpointing individual applications almost impossible. Some times a vehicle manufactured for one state was delivered to another, and dealers traded cars frequently. So dates are relative most of the time.

EEC-IV

EEC-IV has been Ford's computer of choice with enthusiasts for years. Its advanced programming can run almost any engine, while not being over complex. All the necessary engine controls are just as advanced as the newest vehicles coming out. While emissions controls and other secondary devises are easily deleted. EEC-IV uses the same 60-pin connector as III, but one of the indexing tabs on the outside is offset.

EEC-V

*1994

*OBD-II (covered in text below)

EEC-VI

*2003

*Multiple connectors

*No J3 connector for chips, complete Flash Memory capable

Unfortunately American capitalism drives Ford, 'just because you making a new toy doesn't mean you can't sell the old toys until they're gone.' This is called crossover, there were carburetors in 1988, and many other crossovers that make pinpointing individual applications almost impossible. Some times a vehicle manufactured for one state was delivered to another, and dealers traded cars frequently. So dates are relative most of the time.

EEC-IV

EEC-IV has been Ford's computer of choice with enthusiasts for years. Its advanced programming can run almost any engine, while not being over complex. All the necessary engine controls are just as advanced as the newest vehicles coming out. While emissions controls and other secondary devises are easily deleted. EEC-IV uses the same 60-pin connector as III, but one of the indexing tabs on the outside is offset.

The internals of EEC are complex; Intel and Ford had a joint venture building EEC. EEC uses a custom Intel 8061 chip for its processing functions. This chip is modified only for EEC and is soldiered into the computer board. This 8061 processor chip holds the factory fuel injection program and commands the rest of the internal components. There is also a custom Intel 8361 memory chip. The EEC has three different kinds of memory, ROM KAM & RAM. Read Only Memory or ROM; this is the long-term memory where the master program is kept. The ROM cannot be altered and lasts 20 years after the EEC is disconnected from voltage. Keep-Alive Memory or KAM; this is the complex mid term memory; this memory lasts for as long as EEC is receiving 12 volts. The KAM is where the trouble codes are stored, and where the sensor baselines are memorized. Random Access Memory or RAM is the short-term memory; this is where data is stored during a trip. Once the key is turn off the RAM is deleted.

The Intel 8061 processor chip holds the factory fuel injection program and commands the entire system. Within the program are Scalars, Functions, Tables, and Flow Charts. A Scalar is 'a single numerical value assigned a label.' It sounds more complex than it really is. A common easy to understand example is the engine limiter: 'REVLIM = 6000.' Functions are graphs, but Ford like to call them functions. It's usually an input vs an output. So more input causes more output and vise versa. Tables are more complex than functions and are 3 dimensional graphs, when 2 inputs influence an output. The flow charts combine the basic scalars, functions and tables to dictate within the program to calculate an output. Flow charts are more for human understanding than computer function; it helps us to look at a complete thought.

| Scalar | REVLIM =6000 |

|---|---|

| Function | |

| Table | |

| Flow Chart |

The programmed values within the EEC are different for each vehicle/ year / engine / transmission model. Flow-Charts are not changeable, they are forever burned into the processor. These numbers within the scalars, functions, and tables can not be replaced. But they can be substituted with numbers by a chip, more on that later. The EEC only has one or two Flow Charts that are a lot larger than my simple example. The engine Flow-Chart is all combined and creates the system 'Strategies,' a second flow chart can be added for vehicles with automatic transmissions. It runs these flow charts at incredible speeds, a sequential fuel injected V-8 engine needs the injectors, and spark plugs activated 4000 times a second at 6000RPM. EEC-IV operates at 15MHz, that's the ability to do 15,000,000 tasks in one second. But there is more to do than send out a spark signal, reading a sensor takes one task away, EEC-IV has to check sensors in-between firing cylinders. So if you're doing the math, we still have the capability to do 1000 functions in-between injector and spark plug firing. We don't really need to go any further into this boring math, just understand that it works.

There are main strategies that EEC uses to run the engine; and back up strategies for emissions and diagnostics. In each strategy the master Look-Up table must use the sensors PIP, TPS, ECT, MAF or MAP. Those sensors run the show and which part of the flow chart EEC is directed down. The set values that dictate which Strategy to use and when to use them are different for each vehicle application. This table quickly explanes the strategies control of fuel, timing, and emissions, for further information read our Strategies page.

Ford Eec Iv Module

Strategy | Fuel | Spark | Emissions | Sensors |

Start / Crank | Open loop, preset enriched values | TFI controlled | None | RPM / ECT |

Cold Start & Warm Up | Open loop, preset enriched values | ECT Multiplier | Air to CAT | RPM / ECT / ACT |

Cold Drive-Away | ECT < 185° = Enrich ECT > 170° = Lean | RPM vs Load Multiplier ECT Multiplier | Air to CAT | RPM / MAF or MAP / ECT / ACT / TPS |

Warm Idle | Preset Enriched Values | Retard after 1 minute | Maltego xl free license copy. Intermittent Air to CAT | RPM / TPS / ECT / ACT / HEGO |

Warm Cruise | Closed loop: 14.7:1 | RPM vs Load Multiplier ECT Multiplier EGR Multiplier | EGR Canister Purge Air to CAT | RPM / MAF or MAP / TPS / ECT / ACT / EGR / HEGO |

Part Throttle Acceleration | Closed loop: 14.7:1 | RPM vs Load Multiplier ECT Multiplier | Air to CAT | RPM / MAF or MAP / TPS / ECT / ACT / |

Full Throttle Acceleration | Open loop, preset maximum enrichment | RPM vs Load Multiplier ECT Multiplier | None | RPM / MAF or MAP / ECT / ACT / TPS / |

Deceleration | RPM > 1500 = O RPM < 1500 = 15:1 | Preset Advanced Value | Canister Purge | RPM / ECT / TPS / VSS |

EEC-IV is currently our best 'factory' engine computer choice today. The best thing to do is write out a list of goals you wish to achieve, and see what it takes to achieve them. See what aspects of your goals are not so important. Power, Street-ability, Fuel mileage, ease of installation, passing emissions, ease of repair, and the almighty dollar are all factors you need to think about. Many people don't realize the big picture until the picture doesn't work or costs a lot. Plan ahead, ask experienced tuners, racers, and talk to your friends. As a good friend always asked me, 'speed is money, how fast do you want to go?'

EEC-V

Ford Eec-iv Schematic

EEC-V and EEC-IV are alike in a lot of ways; we'll skip to the changes. EEC-V is faster, has more capabilities, and has an easier to alter flash programming. EEC-V has a lot of the same programming it's just harder to read it. EEC-V is 18MHz that's 18,000,000 tasks in a second. For aftermarket needs that is sufficient for everyone's applications. Its internal memory is four times greater than EEC-IV. Today's cars with traction control, air bags, and cruise need these extra capacities. The EEC-V uses a new 104-Pin connector to accommodate more sensors and actuators to help it grow beyond just engine and transmission control.

Ford Eec-iv Wiring Diagram

The new EEC also had to apply to newer 1996 government regulations, these were labeled as 'On-Board-Diagnostics II,' and they required a new test plug called the Diagnostic Link Connector. All brands sold in the USA had to use the same test connector, and it has to be within reach of the driver's seat.

This connector makes inserting a chip into the EEC obsolete. Ford uses this connector to 'upgrade' you're vehicles program, just like a home computer. They plug into the EEC and upload the most current program for emissions, transmission shifting, and other changes that Ford develops after you purchase the vehicle. Technology is being developed to the point where you can add an aftermarket performance programs just as Ford upgrades the stock program. One day we will be able to order an EEC-V from aftermarket with our specifications, engine size, sensors options, and transmission options. You pick the fuel ratios; you pick the timing curve, then wait for the mail, make your wiring harness to the included directions, hook it up and drive. No more searching for the best EEC, no more using just enough sensors to make it happy, and no more using dummy sensors to trick the EEC. As of now aftermarket is able to change the Look-Up-Tables from the Diagnostic Link Connector, and is currently 'hacking' into the programming. The more they learn the more you can alter. Right now EEC-IV is the best Ford EEC to choose for swaps, EEC-V is only a good swap if you're going to use all its vehicle control functions. EEC-VI is starting to hit the streets. EEC-VI will not only replace EEC-V, but make EEC-V more appealing to aftermarket venders. Listen for future technology.